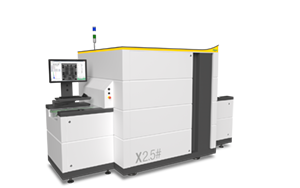

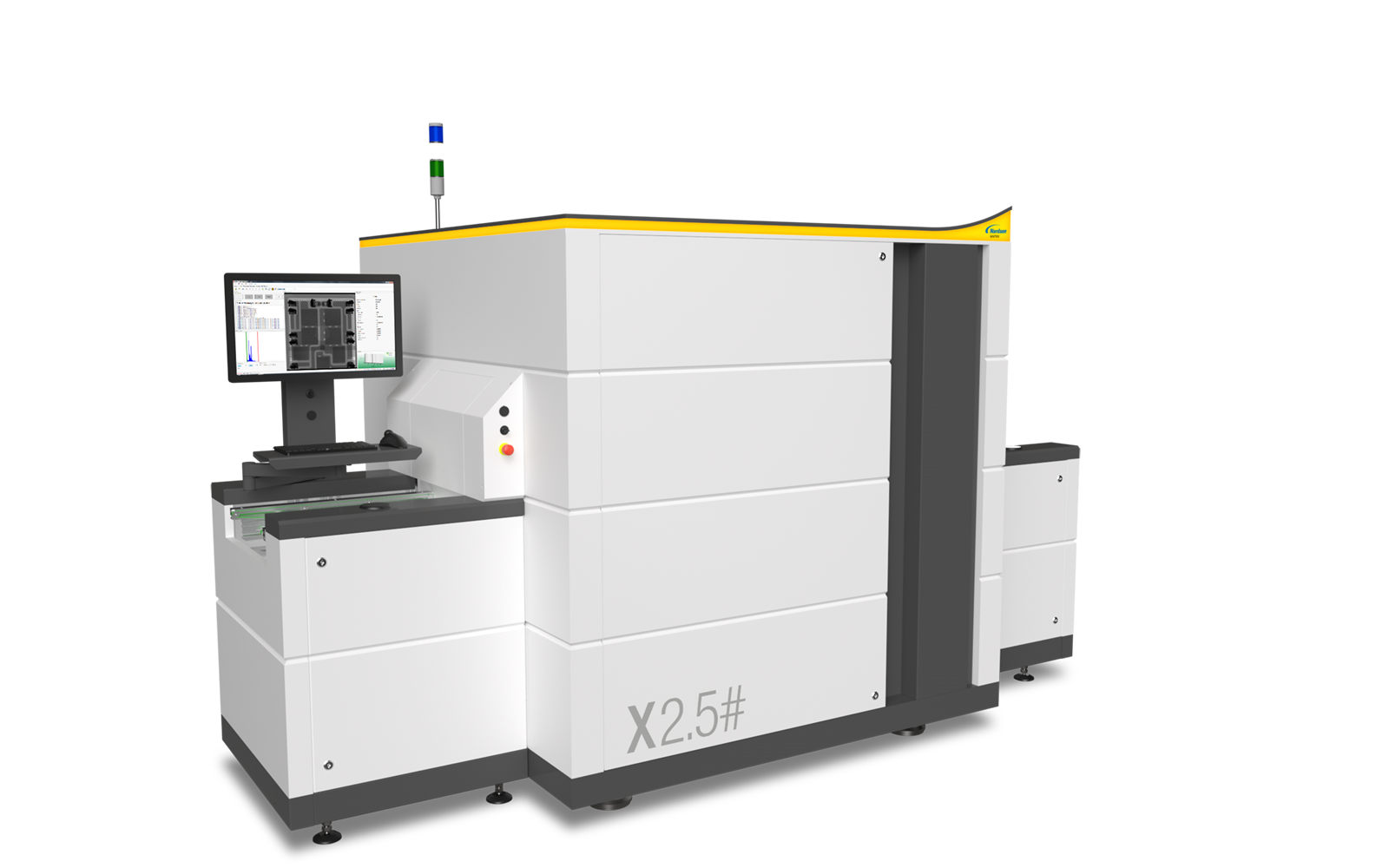

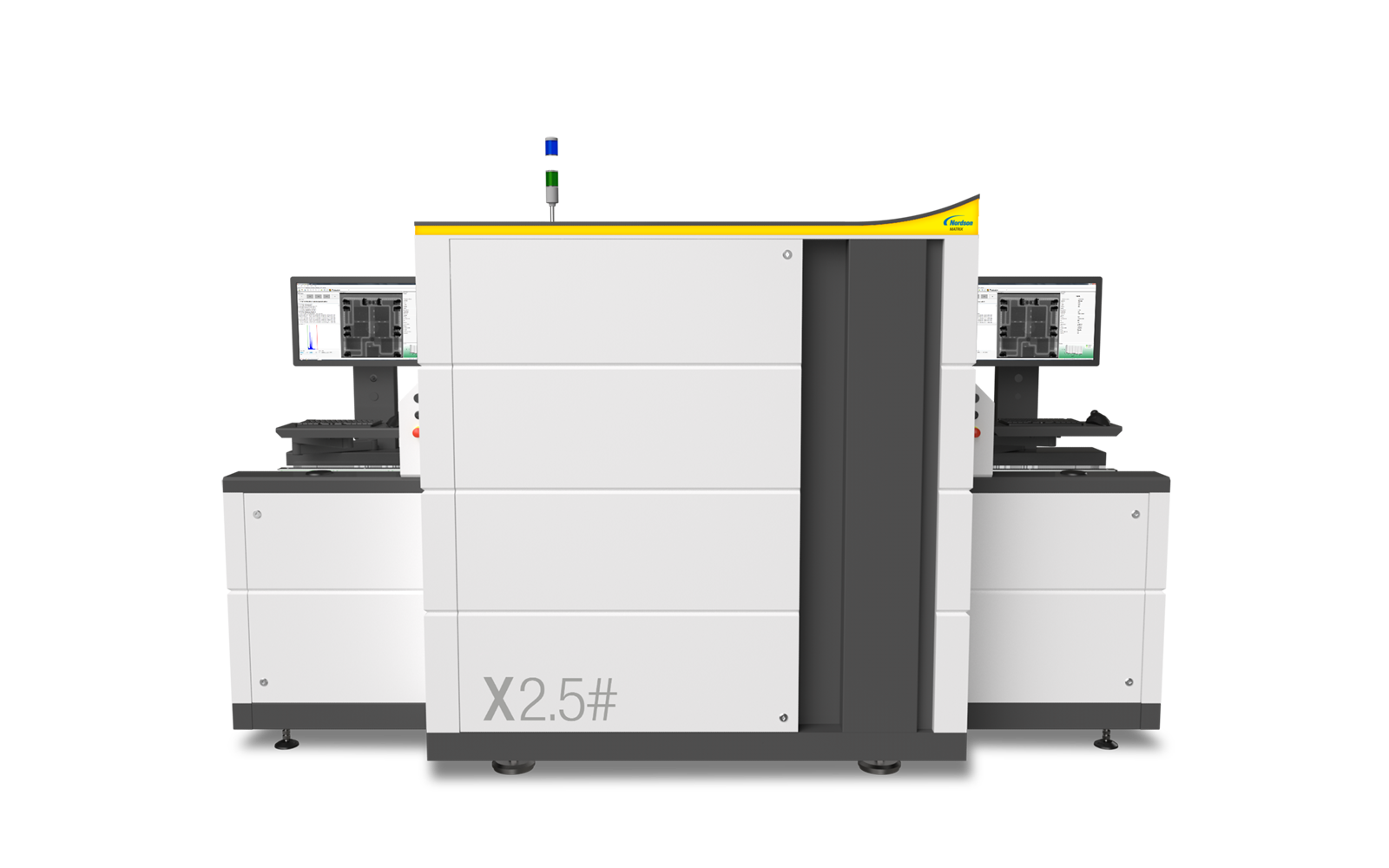

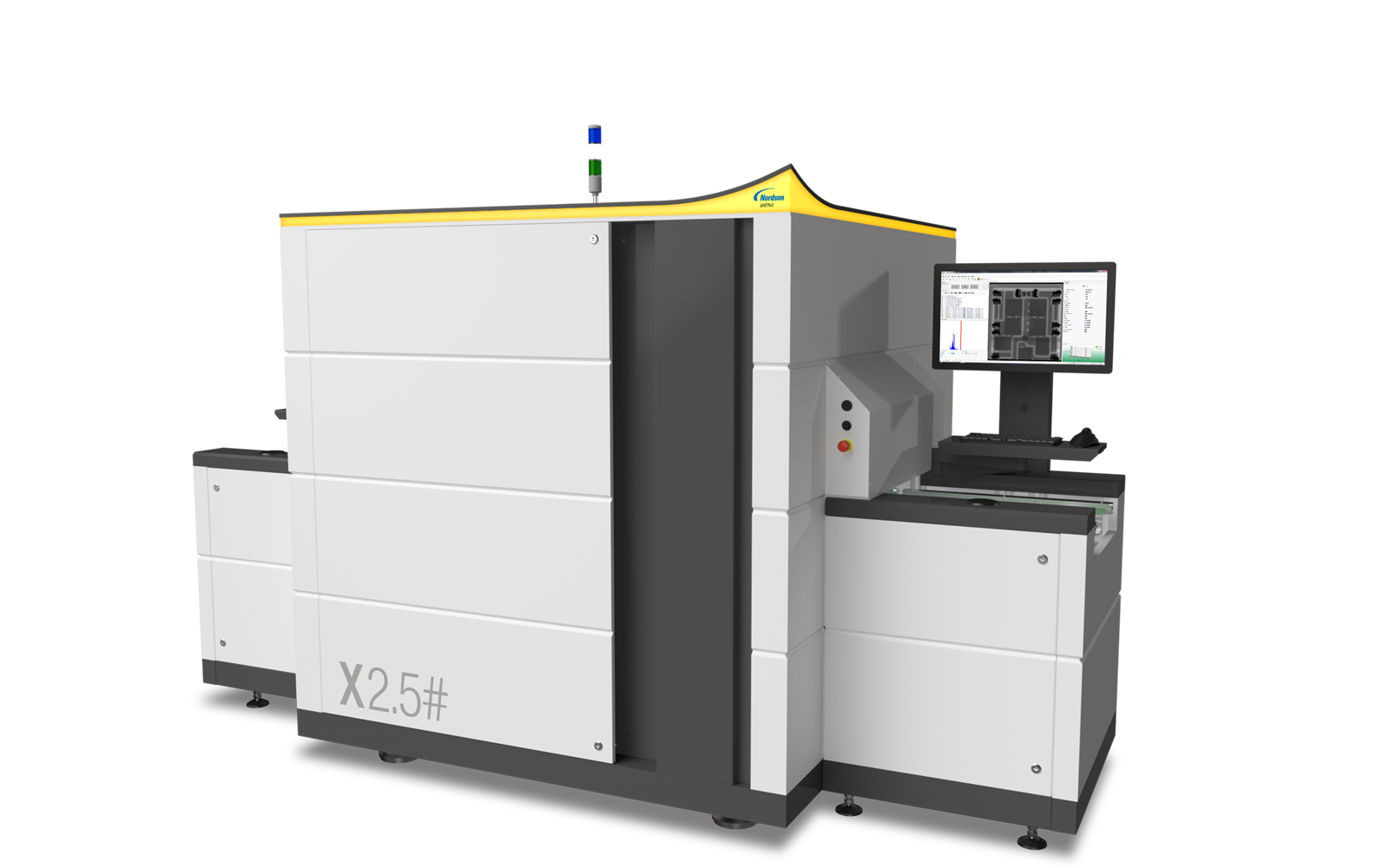

X2.5#

Flexible Inline

AXI system

Description

The MatriX X2.5# is an automated inspection system designed for sophisticated high-speed inspection in SMT production. Transmission X-ray technology with patented Slice-Filter-Technique (SFT) and Off-Axis technology present a reliable solution for the inline inspection of double-sided PCB assemblies. The X2.5# movable detector axes allow high-speed off-axis image acquisition from different angles and directions with maximum image quality and resolution.

X-ray System Features

- Flexible Inline AXI system

- Maintenance free sealed X-Ray tube and digital detector technology

- Automatic grey-level and geometrical calibration

- 5-axes programmable motion system for high speed inspection

- Inline pass through board handling with automatic width adjustment

- Full product traceability via customized MES-Interface

- Optional: Barcode scanner (1D/2D)

Inspection speed

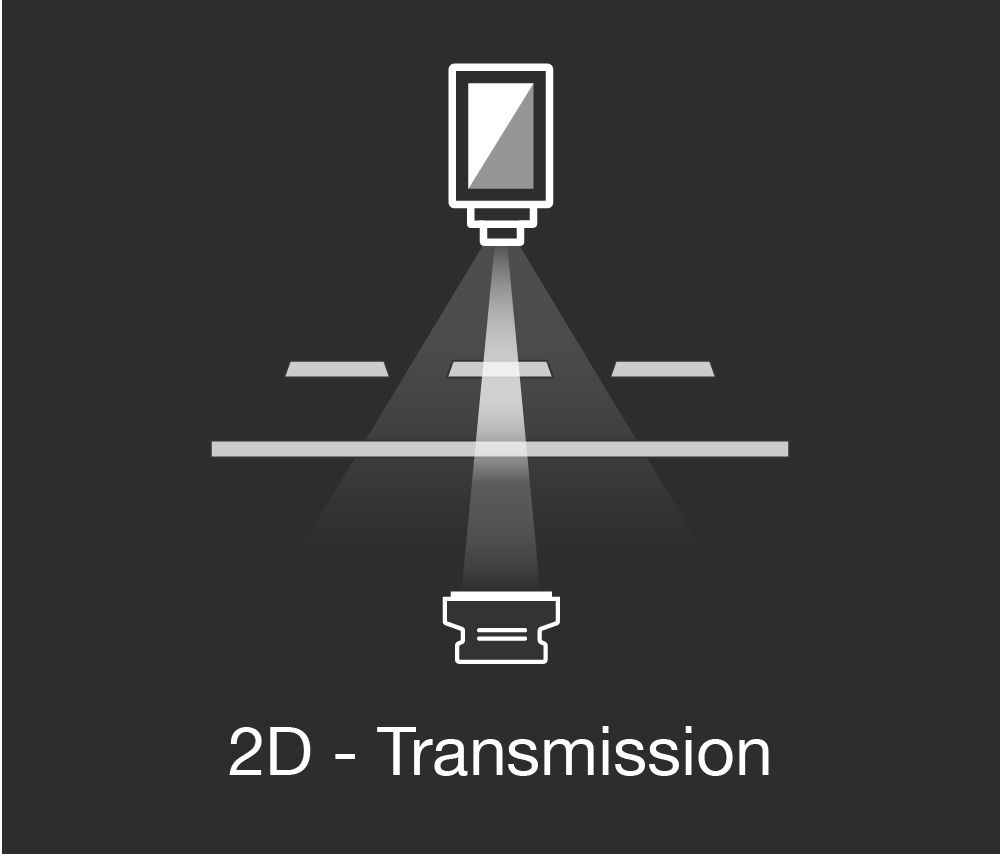

Transmission (2D)

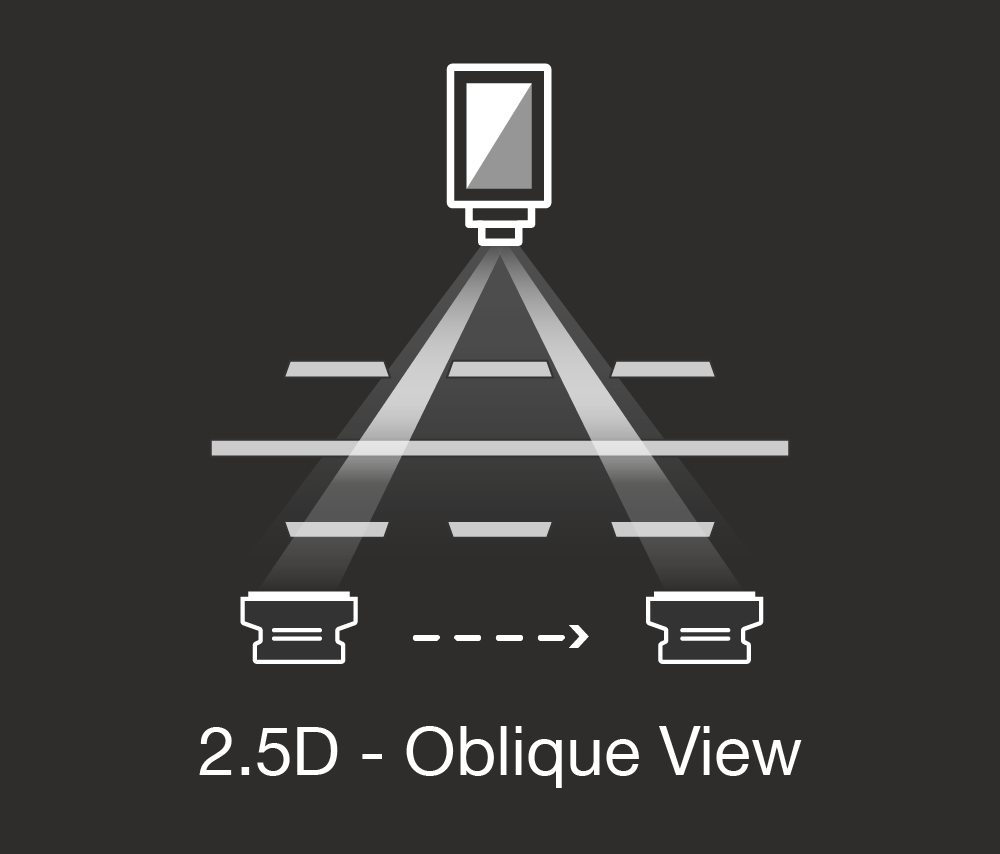

Off-axis (2.5D)

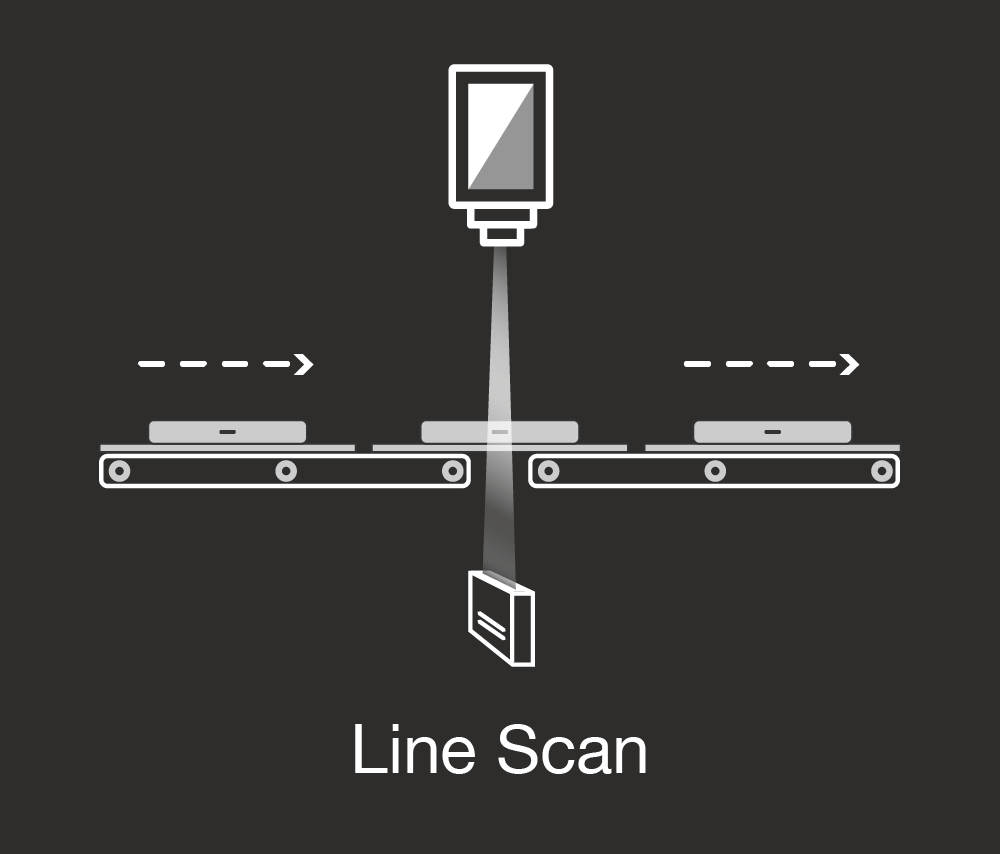

Line scan (2D)

Off-axis (2.5D)

Line scan (2D)

3-4 images/sec

2-3 images/sec

200 mm/sec

2-3 images/sec

200 mm/sec

Microfocus X-ray source (sealed)

standard:

130kV/40W

130kV/40W

optional:

100KV/20W

120kV/40W

150kV/75W

100KV/20W

120kV/40W

150kV/75W

Detector

standard:

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

optional:

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

TDI Line Scan

(12 bit, 2-4k, 48-96 µm)

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

TDI Line Scan

(12 bit, 2-4k, 48-96 µm)

Datasheet X2.5# SMT Setup

Datasheet X2.5# SMT Setup