XCT-Series

High Resolution

Offline AXI platform

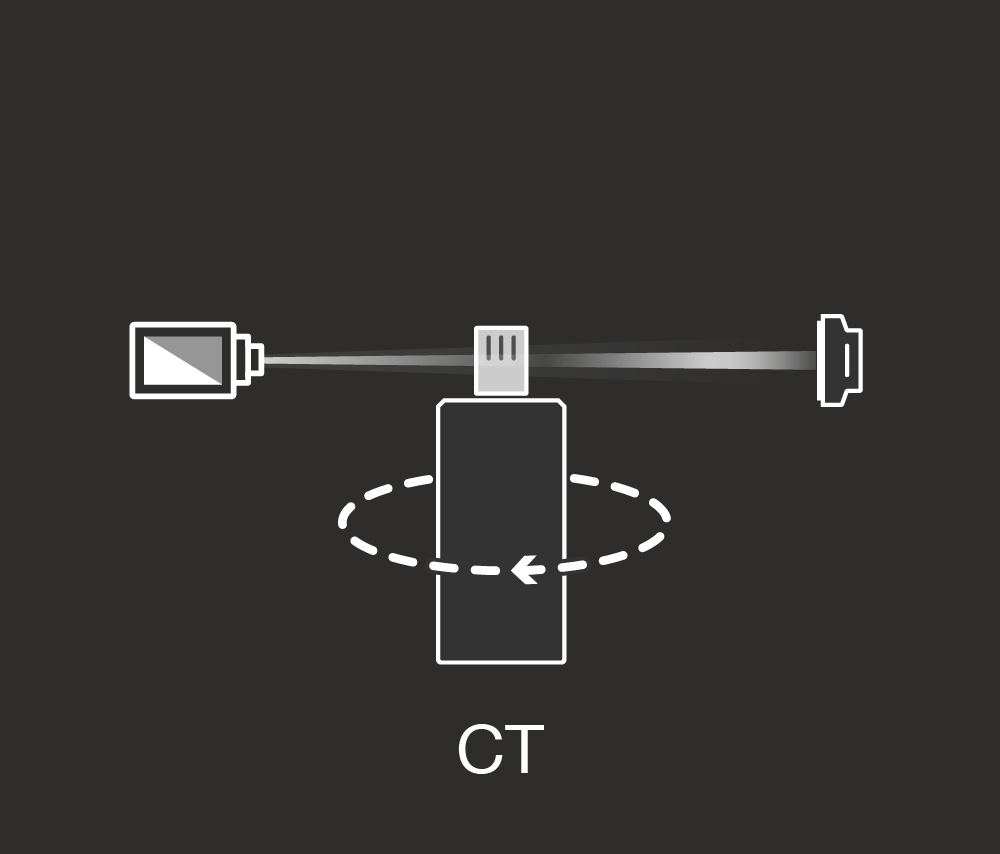

with CT technology

Description

The XCT-series systems are manually loaded, automated X-ray CT systems which offer a solution for a variety of CT applications. These systems provide the highest possible flexibility in order to satisfy individual customer needs. Depending on the application, they can be equipped with different types of tubes and detectors to offer high-resolution or high-power solutions.

Unlike most CT systems, the XCT-1000 features both volume analyzing and automatic processing of the slices. As the newest feature, this machine is available with a super high resolution setup, offering a CT voxel size less than 1µm. It is especially suitable for the inspection of small to medium production volumes or for the use in laboratory environments, production sampling or failure analysis. The applications range from consumer electronics and automotive li-ion batteries, component level inspection for wire bonds, micro-solder-joints on PCB‘s, casting parts and semiconductors.

X-ray System Features

- CT-AXI System for Island and Offline configurations

- Microfocus X-ray tube (sealed tube / maintenance free)

- Multiple programmable motion system with servo drives

- Digital CMOS flatpanel detector

- Automatic grey-level and geometrical calibration

- Barcode scanner for serial number and product type selection

- Full product traceability via customized MES-Interface

Highlights

- Full volume reconstruction

- Automatic slice analyzing

- Generation of report files after each inspection

- Customized part holders

Available Setups

- High Power setup for battery inspection

- High Resolution setup for elecronics and semiconductor applications

Available Configurations

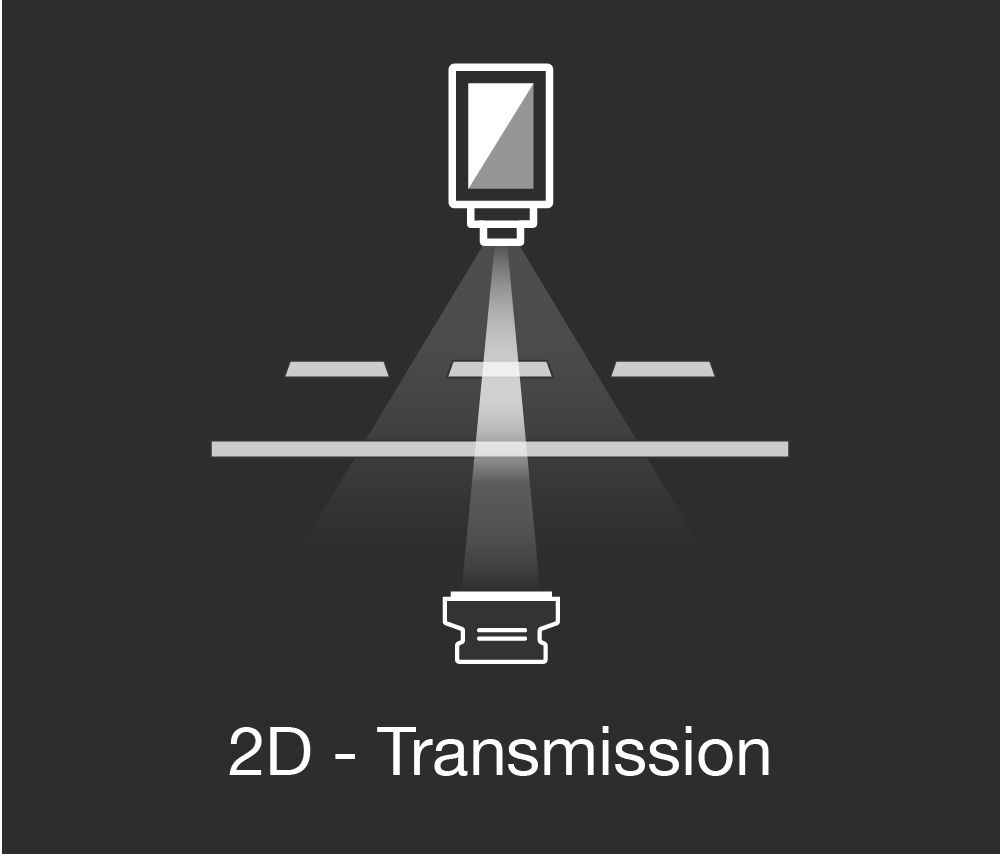

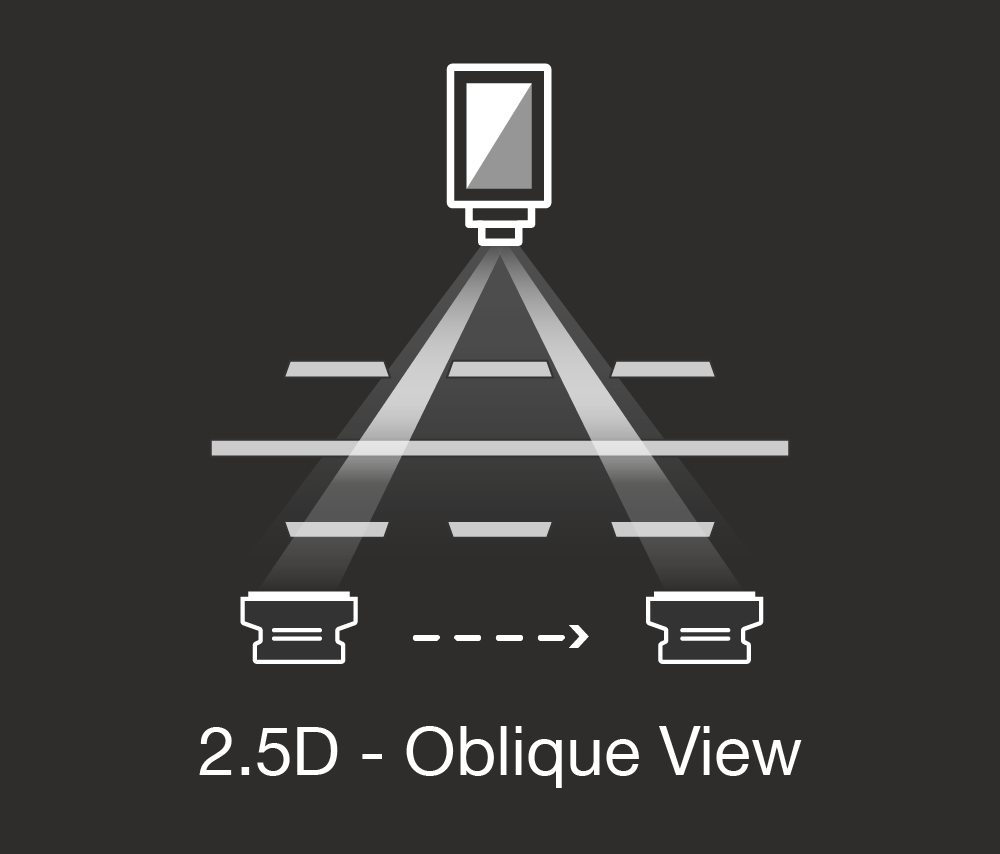

Depending on the type of product & inspection task- XCT-1000 Transmission (2D) + SFT™ + Off-Axis (2.5D) + CT

Datasheet XCT-1000 High Res setup

Datasheet XCT-1000 High Res setup