XT-3

High resolution

AXI system for

off-line use

Description

The XT-3 is a high-resolution manual x-ray inspection system designed to address fast intuitive operation, low volume production capacity, and advanced failure analysis for SMT production inspection and quality control protocols. This system addresses more complex SMT solder-joint and semiconductor inspection and analysis. It is easy to learn and easy to use by all production floor operators, technicians, and engineers. The small footprint allows passage through a standard door width. This system offers exceptional image quality and together with the MatriX Image Processing Software (MIPS) provides industry leading analyzing and automated inspection for BGA, QFN, and Pin-in-Paste or Through-Hole Barrel Fill detection.

X-ray System Features

- High resolution Offline MXI system

- Maintenance free sealed X-Ray tube and digital detector technology

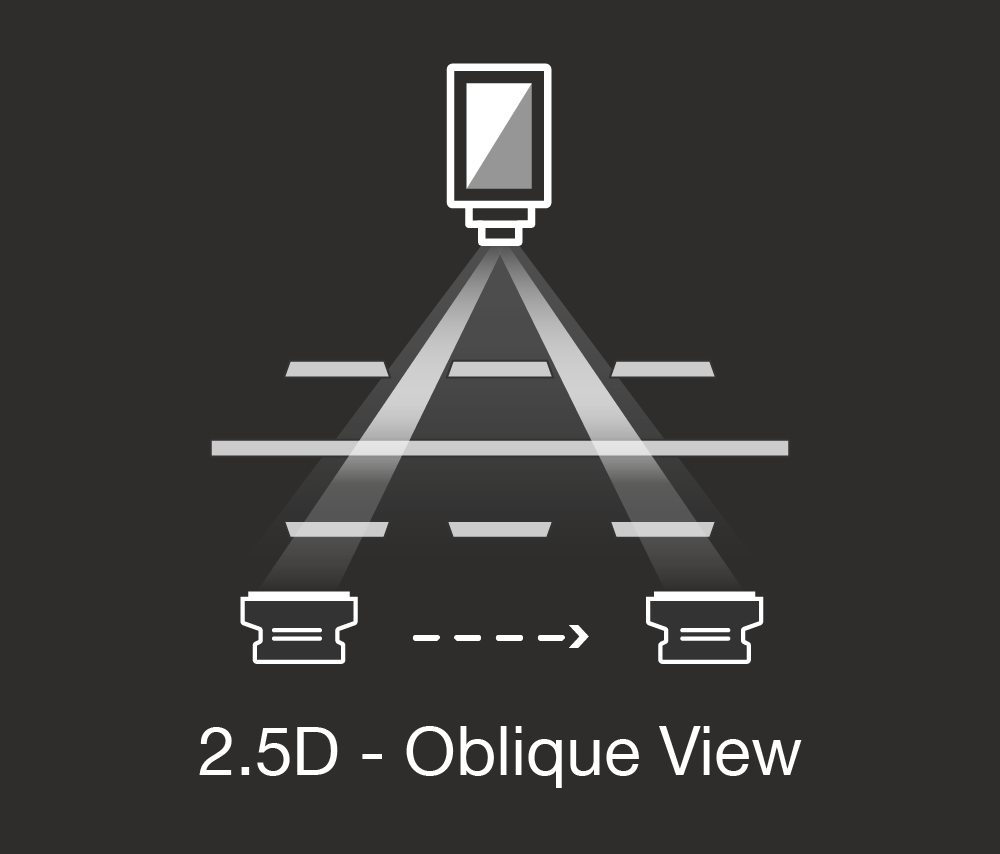

- 3 axes stepper motor drive system with optional tilt & rotate unit for off-axis imaging

- Up to 50 mm programmable, variable field of view

- Teach & Go inspection mode for automatic inspection sequences

Microfocus X-ray source (sealed)

standard:

100KV/20W

100KV/20W

Detector

standard:

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 1k x 1k, 75 µm)

optional:

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

CMOS Flatpanel Detector

(14 bit, 1,5k x 1,5k, 75 µm)

CMOS Flatpanel Detector

(14 bit, 2,3k x 2,3k, 50 µm)

Datasheet XT-3

Datasheet XT-3