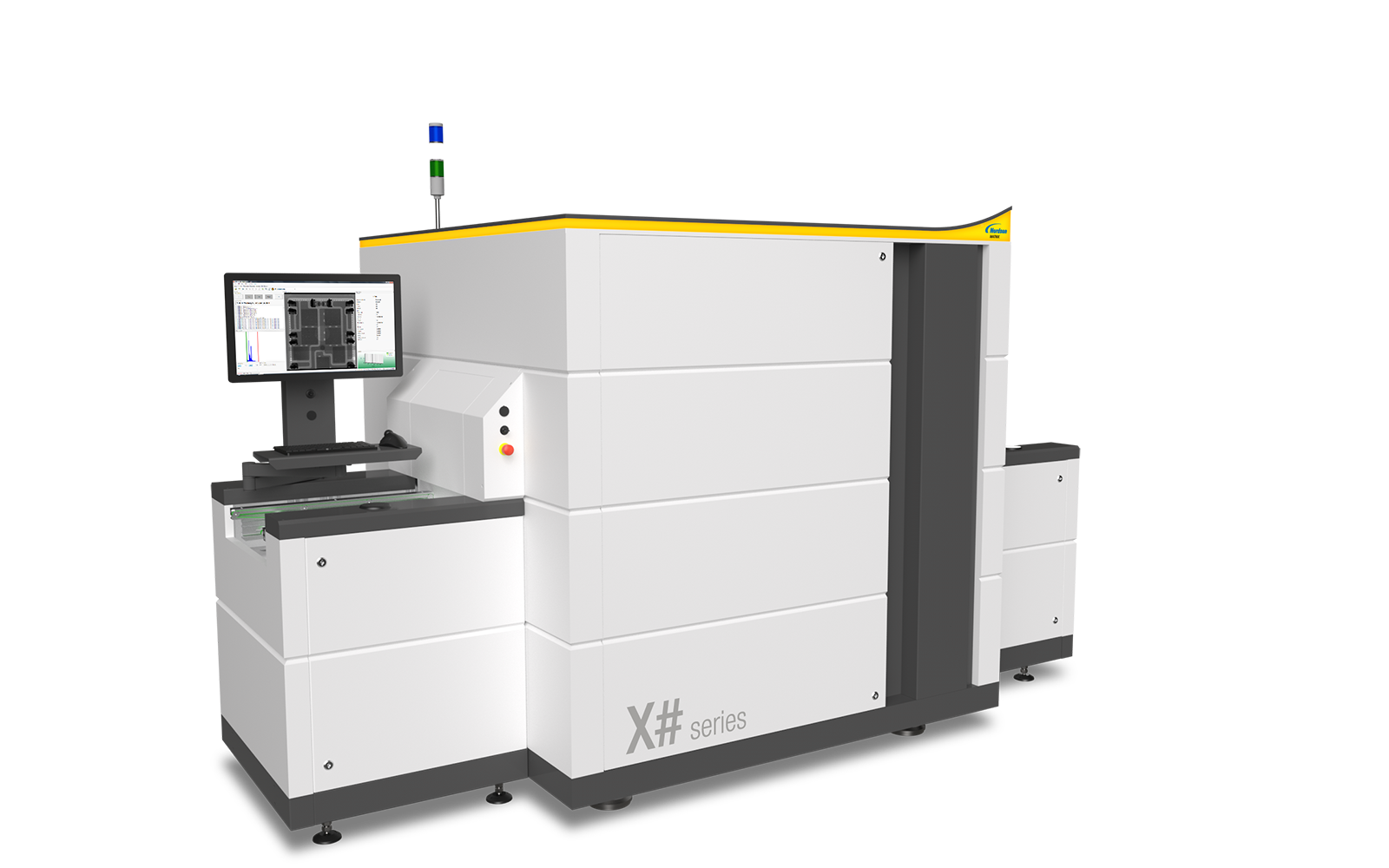

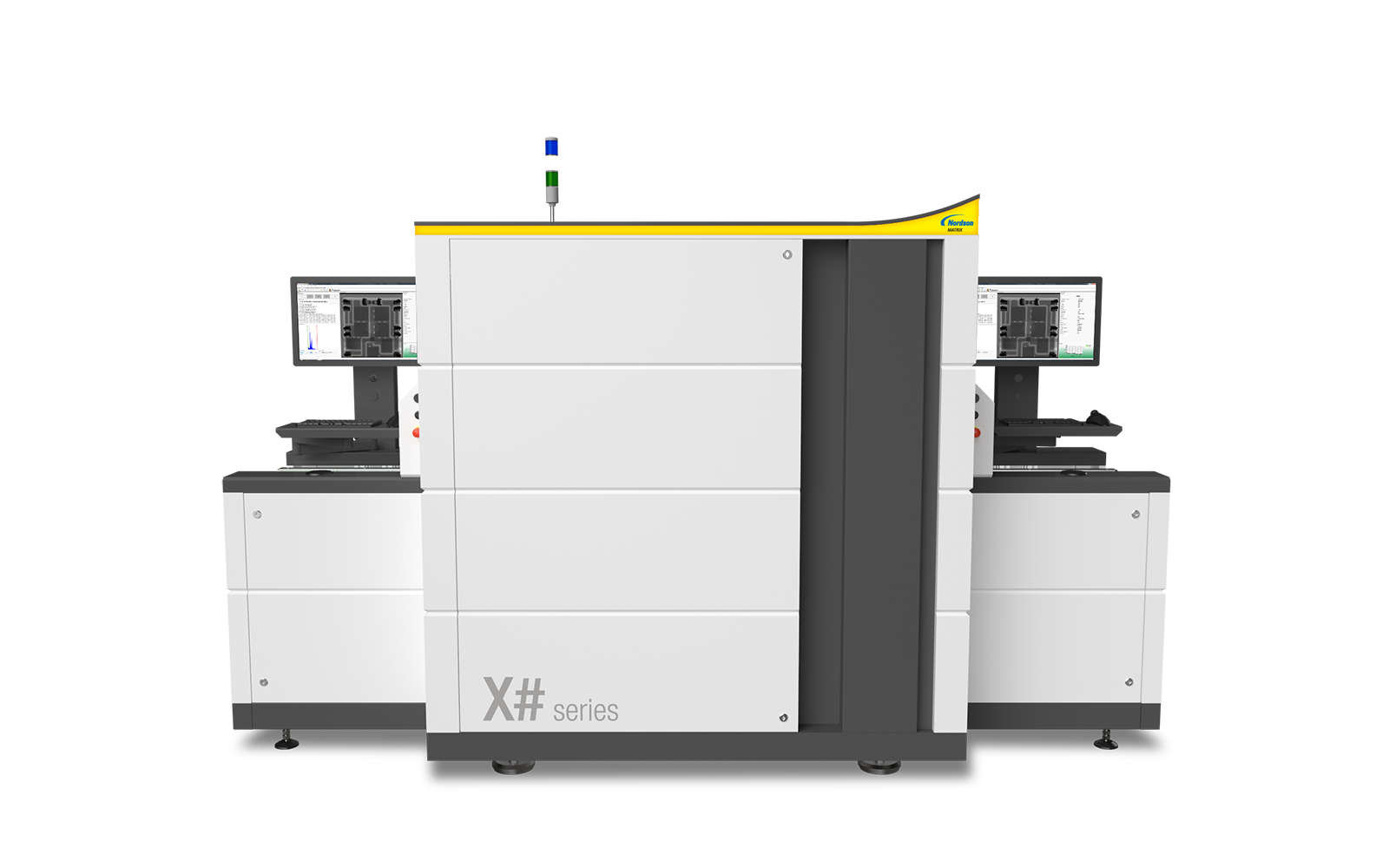

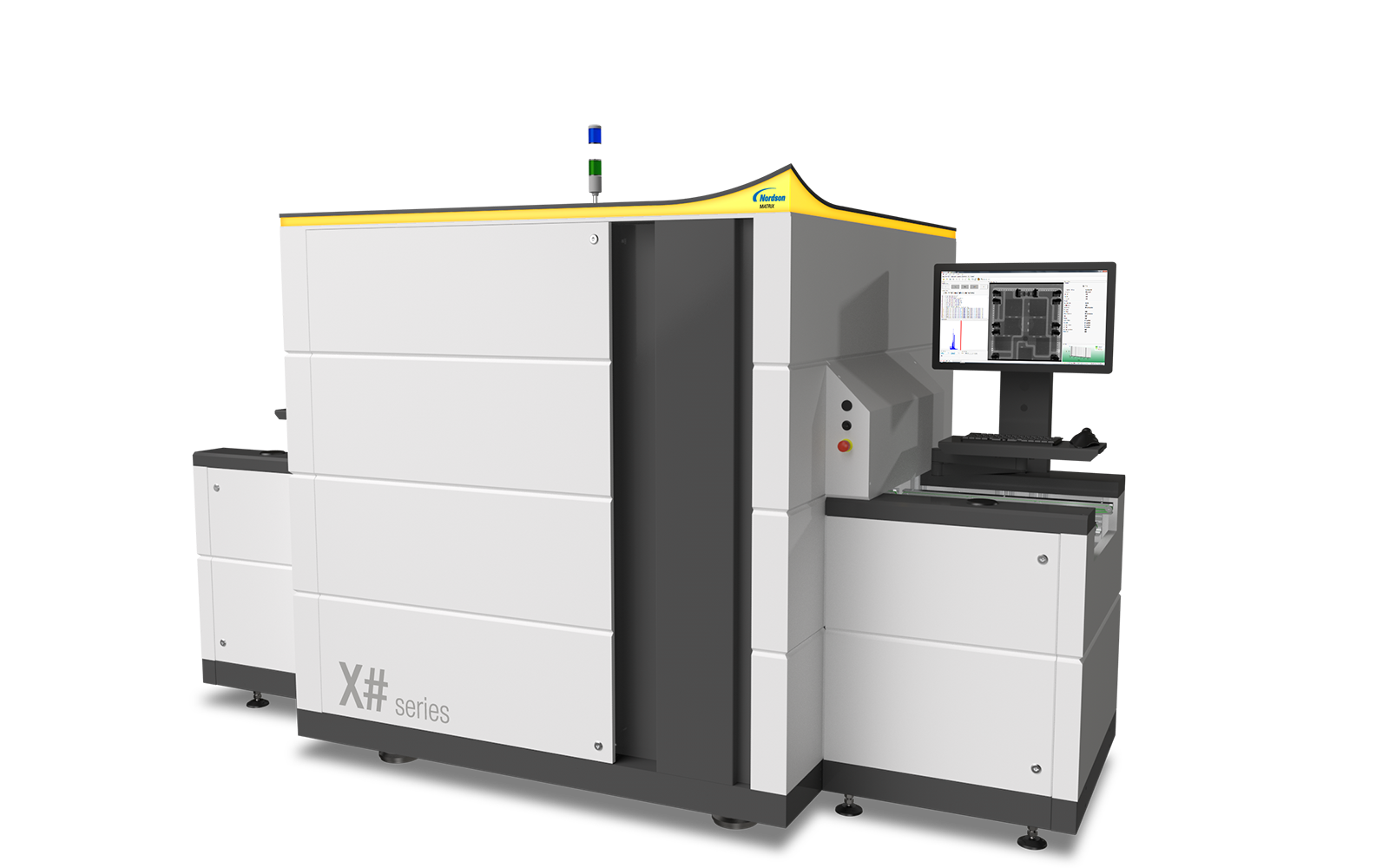

X#-Series

Flexible Inline

AXI platform

Description

The X#-platform series is an inline automated X-ray system which covers a wide range of AXI applications. It is a flexible platform with very versatile fields of use depending on the application requirements. The inspectable applications range from component level inspection for wire bonds, large SMT boards, high-power electronic modules up to fully assembled modules.

X-ray System Features

- Flexible AXI system for inline and island of automation configurations

- Microfocus X-ray tube (sealed tube / maintenance free)

- Multiple programmable motion system with servo drives

- Digital CMOS flatpanel detector

- Automatic grey-level and geometrical calibration

- Barcode scanner for serial number and product type selection

- Full product traceability via customized MES-Interface

Highlights

- Flexible setup for inline pass through or same-side in/out configuration

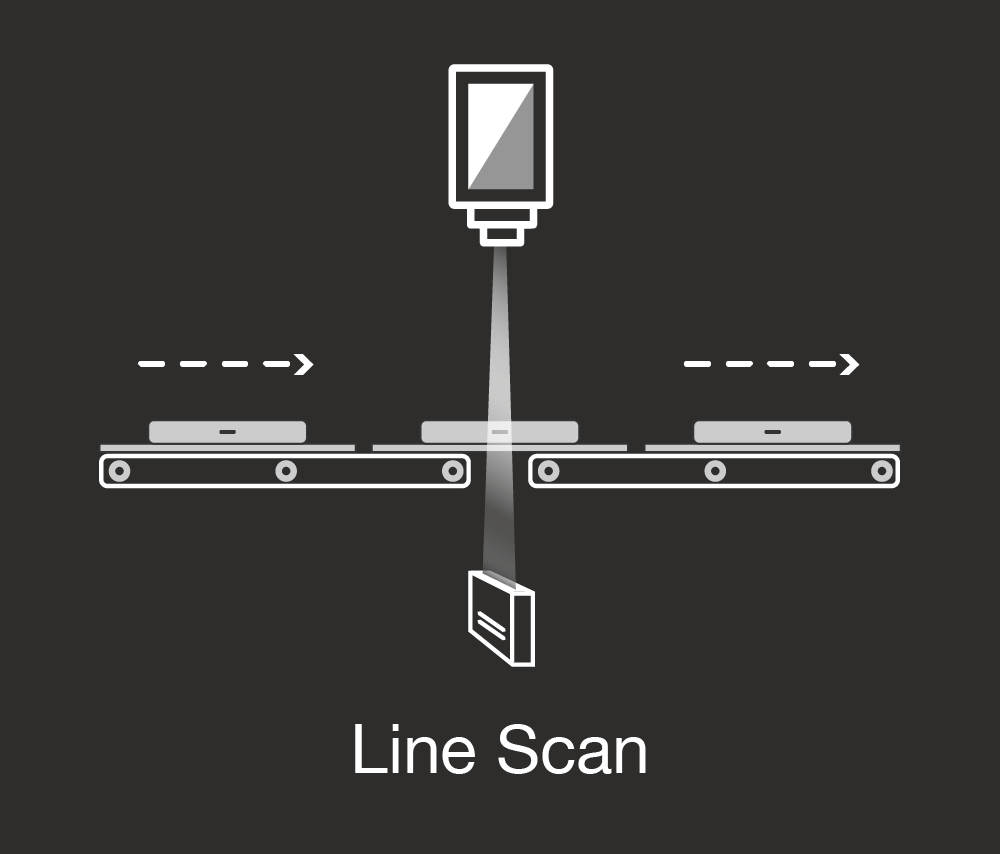

- Combination with line scan camera for high throughput

- Auto BCR scanning station (x-y gantry)

- Low-dose radiation filter

Available Setups

- SMT setup for component and solder-joint inspection on PCB

- High Resolution setup for chip level assembly

- Final Assembly and Test (FATP) setup for complete modules and consumer products

- High Power setup for power hybrid/IGBT devices and battery

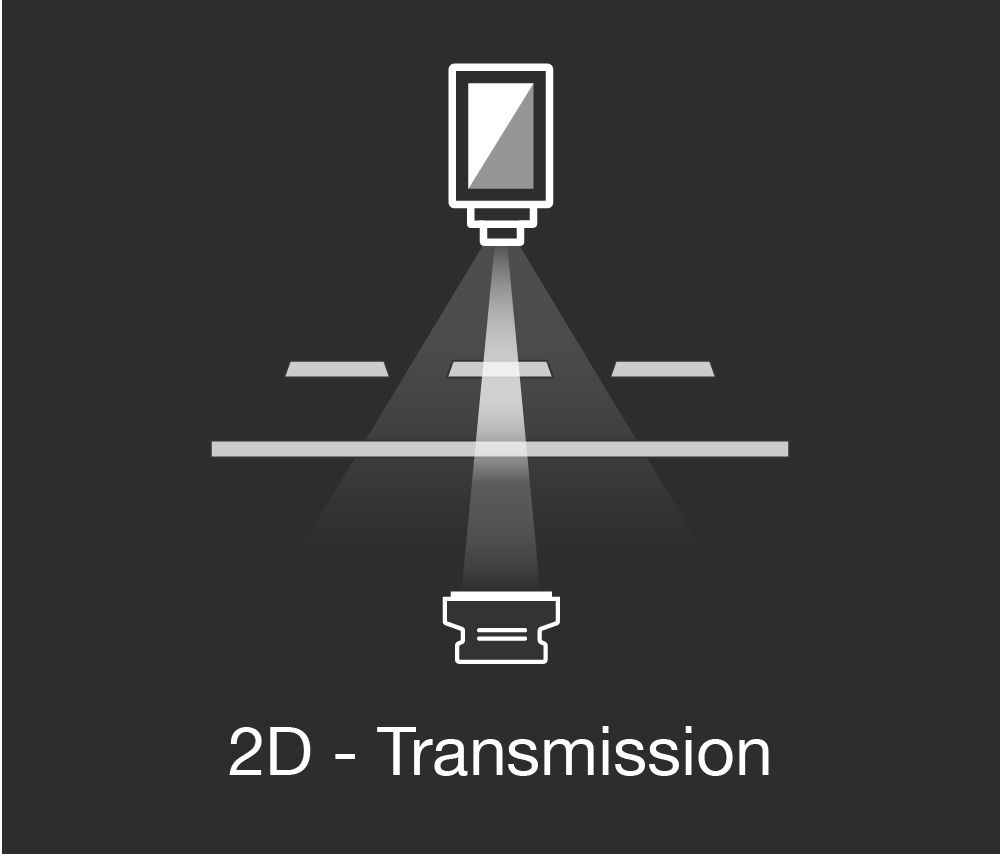

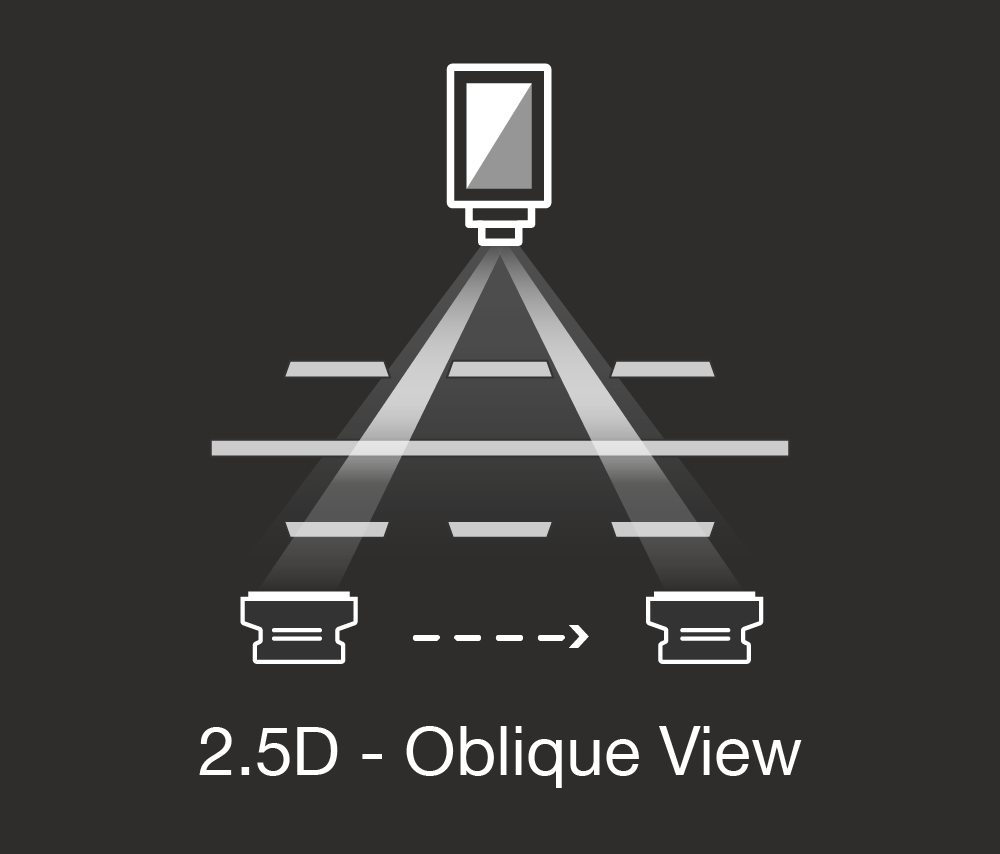

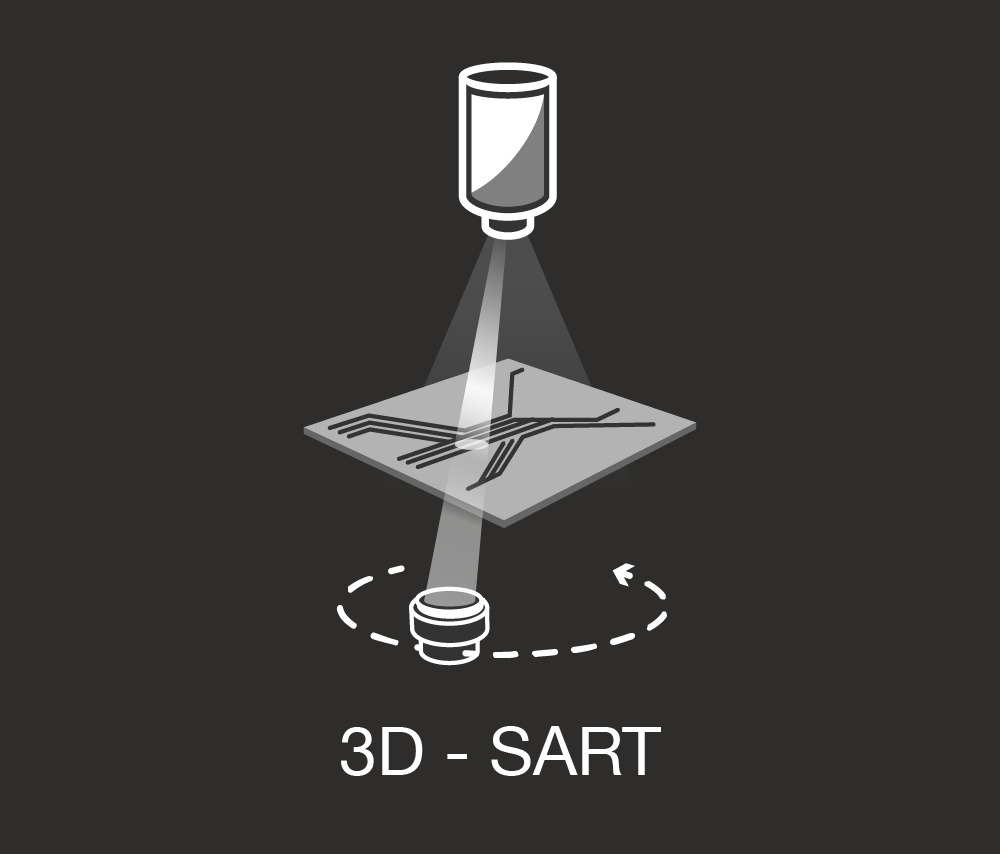

The platform features up to 4 advanced technologies in one system: Transmission X-ray imaging (2D) with patented Slice-Filter-Technique™ (SFT), Off-Axis technology (2.5D) and 3D SART (Simultaneous Algebraic Reconstruction Technique).

Available Configurations

Depending on the type of product & inspection task- X2# Transmission (2D) + SFT™

- X2.5# Transmission (2D) + SFT™ + Off-Axis (2.5D)

- X3# Transmission (2D) + SFT™ + Off-Axis (2.5D) + 3D SART

Datasheet Xhash-series FATP setup

Datasheet Xhash-series FATP setup