XT-Series

Universal Offline

AXI systems

Description

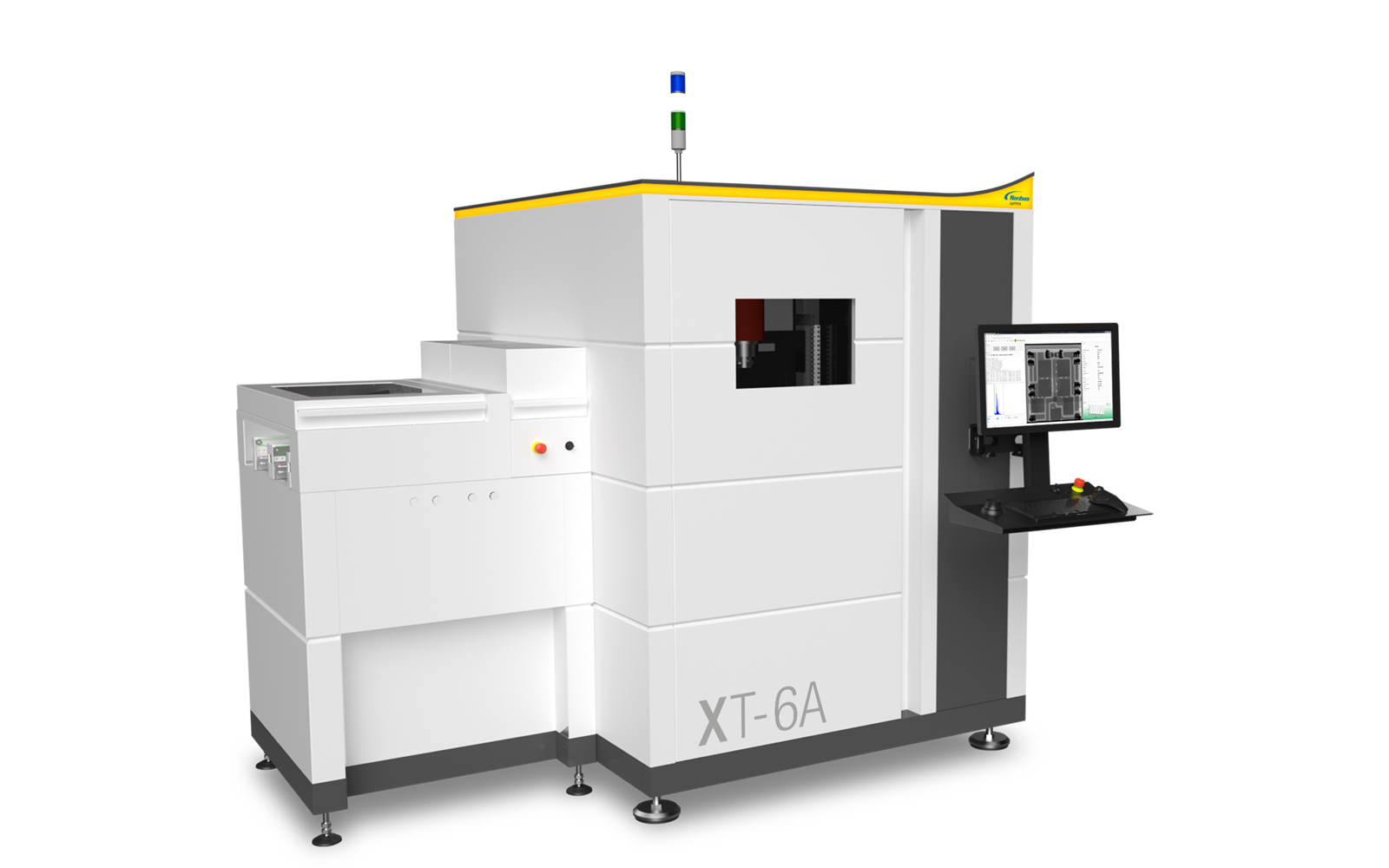

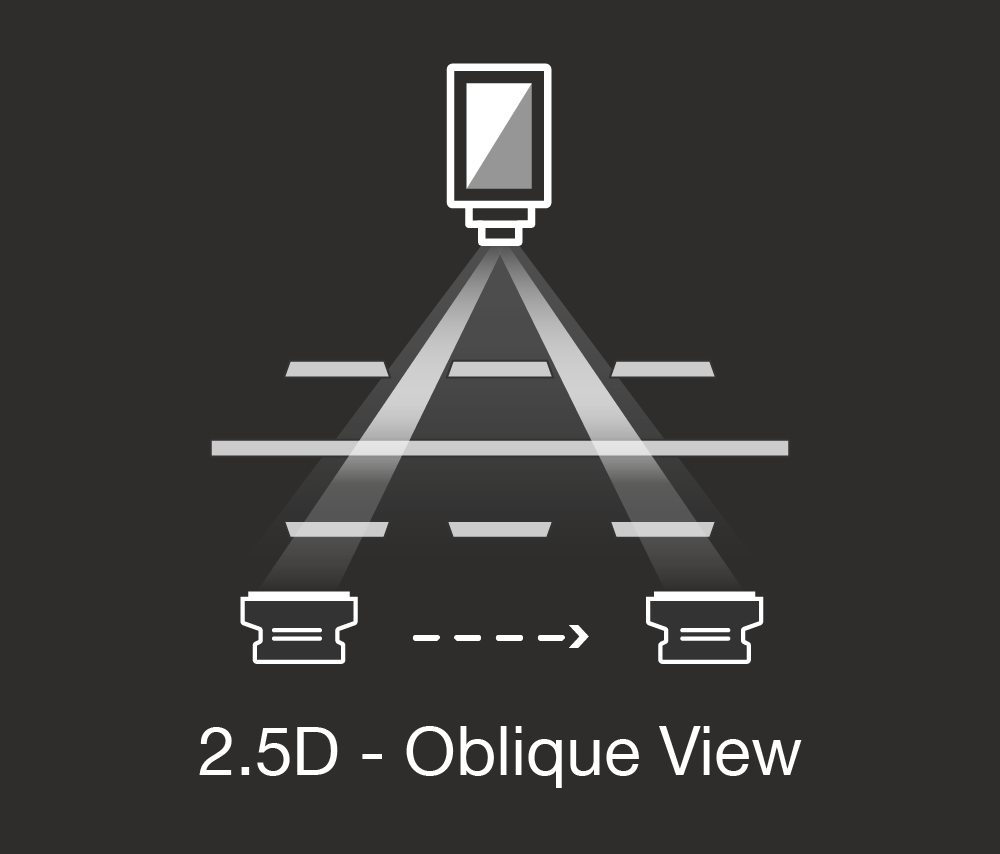

The XT-series provides the advanced inspection capability of Nordson MATRIX‘s inline system in a smaller footprint manual load/island of automation system. The platforms are designed for flexibility and ease of use for a wide variety of products requiring 2D and 2.5D automated X-ray inspection.

The XT-6/XT-6A platform is a highly flexible automated X-ray inspection system with minimum footprint and a parallel-kinematic Hexaglide manipulation unit for extreme-angle off-axis image acquisition with high resolution. It is suitable for high-quality X-ray analysis of electronic assemblies and material analysis of parts that require flexible part manipulation with multiple inspection angles. For batch modes and volume inspection the XT-6 can be equipped with a single-sided conveyor setup and magazine load/unload station (XT-6A).

X-ray System Features

- Flexible AXI system for manual load and island of automation configurations

- Microfocus X-ray tube (sealed tube / maintenance free)

- Extreme angle shot capability (up to 65 deg)

- Multiple programmable motion system with servo drives

- Digital CMOS flatpanel detector

- Automatic grey-level and geometrical calibration

- Barcode scanner for serial number and product type selection

- Full product traceability via customized MES-Interface

Highlights

- Barcodereader

- Heavy duty transport system

- Low dose radiation filter

- Hybrid or chip level assembly setup

Available Setups

- SMT setup for component and solder-joint inspection on PCB

Available Configurations

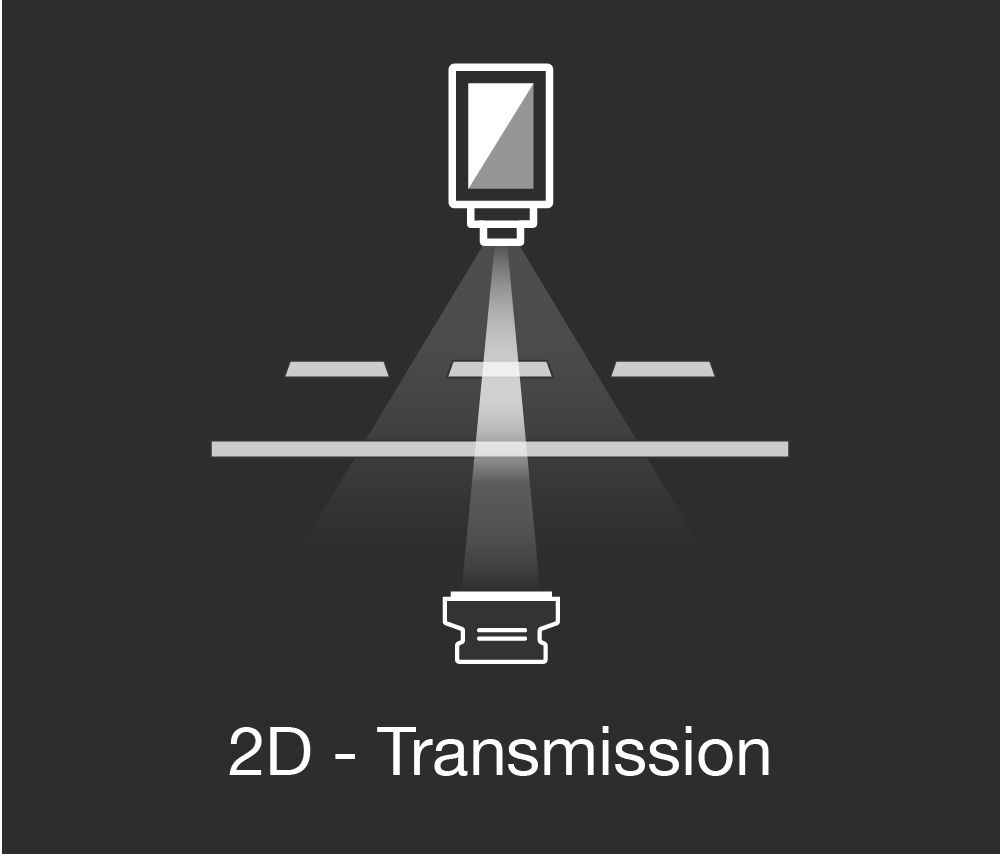

Depending on the type of product & inspection task- XT-6(A) Transmission (2D) + SFT™ + Off-Axis (2.5D)

Datasheet XT-6(A) SMT setup

Datasheet XT-6(A) SMT setup